It’s not just about moving dirt.

It’s about doing it faster, cleaner, and with fewer headaches down the road.

When maintaining gravel roads, leveling farm lanes, or prepping job sites, choosing the right grader blade for your tractor is key to ensuring the job is done efficiently and correctly.

At RoadRunner Equipment, we understand the importance of using the right tool for the job. That’s why we’ve designed our grader blades to meet the needs of tractor owners, equipment dealers, and business owners alike.

But not all grader blades are created equal.

From tractor horsepower to blade width, durability to adjustment features, there’s a lot to consider. For dealers and business owners, making the right recommendation (or investment) means fewer callbacks, longer-lasting performance, and happier customers.

If you’re looking to get the best out of your equipment, RoadRunner Equipment offers high-quality grader blades designed to fit a variety of tractor sizes and applications.

Let’s break down everything you need to know when selecting the perfect grader blade for your tractor.

Don’t Have Time to Read? Here’s a Summary

Choosing the right grader blade for your tractor is about more than size—it’s about matching horsepower, width, durability, and adjustability to the job. In this guide, Roadrunner Equipment breaks down what to look for when buying or recommending a grader blade that performs reliably for years.

Key Takeaways:

-

Match blade to horsepower:

-

C-Series (40–90 HP) for small farms, rural properties, and light-duty work.

-

B-Series (90+ HP) for heavy-duty grading, road maintenance, and construction.

-

-

Blade sizing: Choose a blade slightly wider than your tractor’s rear tires. Roadrunner offers 6’–14’ options, with dual blades for deeper, faster cuts.

-

Built to last: Made in the USA with reinforced steel, heavy welds, and replaceable wear strips for long-term performance.

-

Adjustability matters: Hydraulic tilt, pitch, and crown control features give operators better grading precision and drainage results.

-

Quick-hitch compatible: Category 1 & 2 setups make swapping attachments easy.

-

Use cases:

-

C-Series: Driveways, farm lanes, and small roads.

-

B-Series: Large construction, county road maintenance, and fieldwork.

-

-

For dealers: Recommending the right blade means fewer warranty issues, happier customers, and repeat business.

Bottom line:

Roadrunner’s American-made grader blades are built for performance, longevity, and precision—backed by a 3-year warranty and real customer support.

Horsepower Compatibility: Start with the Machine

Before anything else, it’s essential to understand how your tractor’s horsepower (HP) affects the choice of the right grader blade. The blade needs to match the pulling power of the machine. Too much blade on too little horsepower? The tractor struggles, your productivity tanks, and wear-and-tear increases. Too little blade on a high-powered machine? You’re leaving capacity—and money—on the table.

At RoadRunner, we recommend the following:

- C-Series Grader Blades

Designed for tractors with 40–90 HP, these blades are ideal for:- Small farms

- Rural property owners

- Landscaping contractors

- Municipalities with lighter utility tractors

- B-Series Grader Blades

Built for 90+ HP tractors, these workhorses shine in:- Road maintenance for townships or counties

- Large construction firms

- Agricultural operations with large field tractors

- Equipment dealers servicing high-power fleets

This simple match—tractor HP to blade class—saves a lot of headaches down the road.

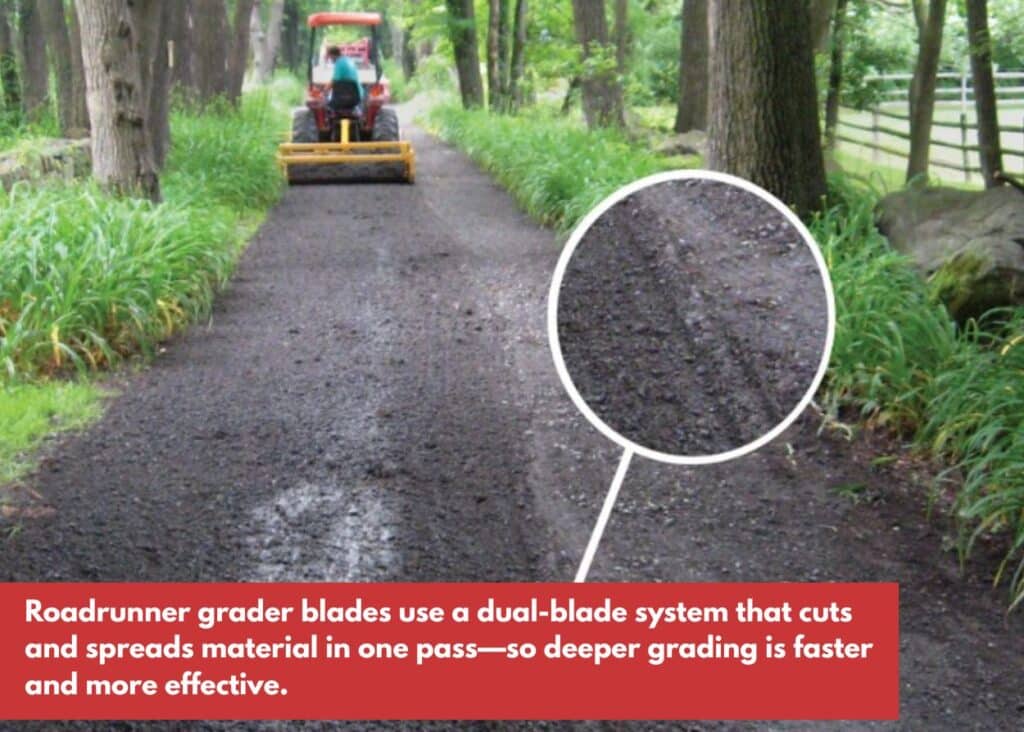

Blade Width & Cutting Depth: Size for the Job

When it comes to grader blades, bigger doesn’t always mean better. The key is choosing the correct width and cutting depth for the job at hand.

A grader blade that’s too wide can make tight turns impossible. One that’s too narrow will take twice as many passes to get the job done.

Here’s a simple guideline for selecting the proper blade width:

- Choose a blade that’s slightly wider than your tractor’s rear tires. This ensures full coverage in each pass while maintaining control and stability.

- For tight areas or residential use, a narrower blade may be needed to ensure easier maneuvering.

At Roadrunner, we offer blades ranging from 6’ to 14’, with custom sizing available depending on your needs.

But width isn’t the only sizing spec that matters.

You also need to consider cutting depth, especially if you’re dealing with hard-packed gravel, clay, or uneven terrain. Roadrunner grader blades use a dual-blade system that cuts and spreads material in one pass—so deeper grading is faster and more effective.

Key sizing questions to ask:

- How wide is the tractor and the road/path to maintain?

- What kind of material is being graded?

- Will this be used in open fields or tighter residential lanes?

- Does the blade need to fit on a trailer for transport?

Material Quality & Blade Durability: Don’t Skimp Here

Grader blades take a beating.

That’s why steel quality and construction are critical. The market is full of offshore-made blades with weaker frames, lower-grade welds, and subpar wear components. They might look good on Day 1—but give it a year, and you’ll be replacing worn-out cutting edges or re-welding cracked frames.

At RoadRunner, durability is non-negotiable.

Here’s why you should choose RoadRunner grader blades:

- Made in the USA – We take pride in offering high-quality, American-made products. Better steel. Better craftsmanship. Better longevity.

- Heavy-duty construction – Our blades are built with reinforced steel, featuring heavy-duty welds and gussets to prevent flex and ensure longevity under load.

- Replaceable wear strips – Bolt-on cutting edges that can be easily flipped or replaced, ensuring your blade lasts longer.

- Reinforced frames and blade mounts – Designed to reduce vibration and stress, especially when working on rough surfaces.

Roadrunner grader blades are manufactured in Pennsylvania and built to outlast the competition. You’re not just buying an attachment—you’re investing in reliability.

Blade Adjustment Features: Control = Results

This is where pro-level blades separate themselves from the pack.

If you’re serious about road maintenance, you need control over the blade’s pitch, tilt, and angle. Different terrains, materials, and weather conditions demand different setups.

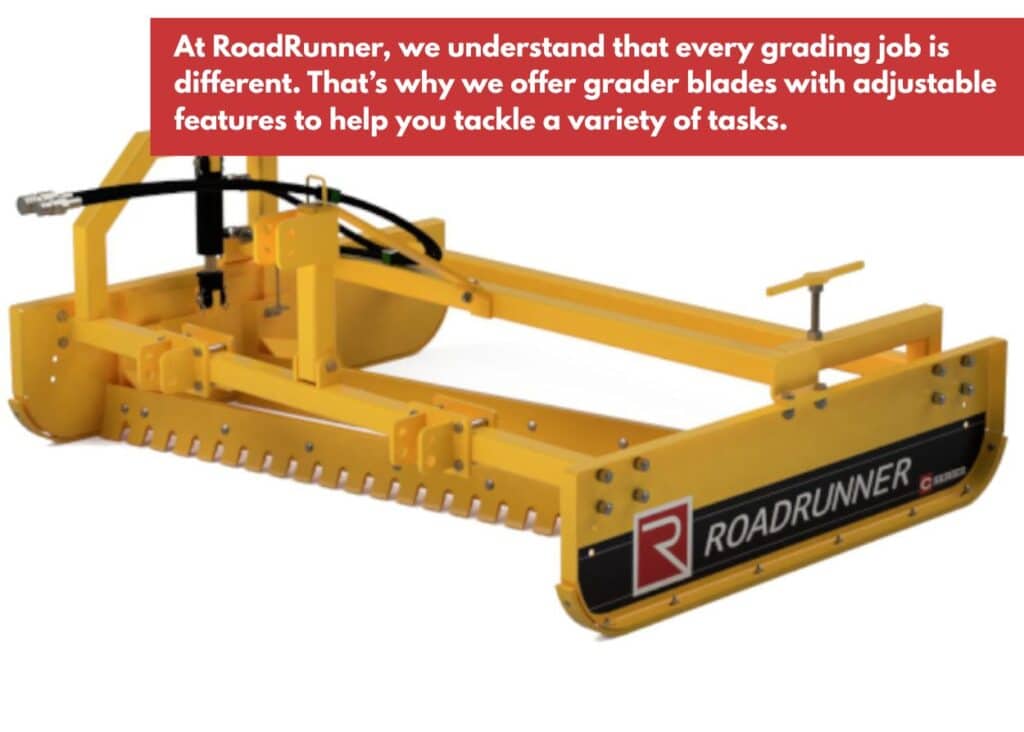

At RoadRunner, we understand that every grading job is different. That’s why we offer grader blades with adjustable features to help you tackle a variety of tasks, including:

Crown Control

Most gravel and dirt roads need a crown—so water sheds off instead of pooling and creating potholes. A good grader blade should allow the operator to easily adjust the center crown to promote proper drainage.

Tilt and Angle Adjustments

Some blades offer manual adjustments only. Others (like Roadrunner) offer hydraulic options for:

- Tilt (for ditching, shoulder work, or slope grading)

- Side shift (to work close to fences or obstacles)

- Pitch angle (to increase cutting aggressiveness or reduce drag)

These adjustments help with precision grading—fewer passes and better results.

Quick-Attach Compatibility

Need to switch between implements frequently? Look for grader blades with Category 1 or 2 quick-hitch compatibility. This saves time during transitions and reduces frustration for the operator.

Application-Specific Use Cases: Know Your Needs

Different jobs = different blades. And if you want to get the most out of your equipment, it pays to match the blade to the task.

Let’s break down some everyday use cases so you can recommend or choose the right tool for the job.

Grading Gravel Roads

The C-Series is a strong pick for most residential and light-use roads. But suppose you’re handling long stretches of county roads or doing frequent maintenance. In that case, the B-Series steps in with more power and durability. Look for a blade with crown control and aggressive cutting edges to keep your road surfaces draining well and staying smooth. If you’re dealing with compacted sections, ripper teeth can be a game-changer by loosening things up before you grade.

Farm Lanes and Pasture Access

A C-Series blade works well here, especially when you’re trying to keep muddy or rutted paths passable.

For tractors in the 50–70 horsepower range, a 6- to 8-foot blade offers just the right balance of coverage and control. Rippers can be helpful after a wet season, though they’re not always necessary.

Construction and Site Prep

Now you’re in B-Series territory. These blades are built for deeper cuts and heavy-duty use. Hydraulic adjustments are worth the investment if you’re contouring ground, digging shallow ditches, or managing large surface areas. For best results on hardpack or subgrade work, choose a blade with skid-resistant cutting edges.

Residential and Landscaping Projects

Stick with a compact C-Series blade—something in the 6- to 7-foot range. That’s ideal for tighter spaces, such as driveways or landscaped paths. Manual tilt and pitch settings are usually sufficient for contractors doing occasional regrading or driveway installations. It’s a smart, nimble option that doesn’t sacrifice performance.

Bonus for Dealers: Why It Pays to Recommend the Right Blade

As a dealer or equipment supplier, your customers trust you for more than just sales. They want honest advice that makes their work easier.

Helping them choose the right grader blade:

- Boosts your credibility—they’ll come back for other attachments

- Reduces warranty issues—because you sized the blade properly

- Improves their satisfaction—which means word-of-mouth referrals

And with Roadrunner’s 3-year manufacturer warranty, you’ve got extra peace of mind. These grader blades are built to last and backed with personal customer support from a small, family-owned company.

That’s something big brands can’t replicate.

Final Thoughts: Invest in What Works

Choosing the right grader blade isn’t complicated when you know what to look for.

Start with horsepower. Size it for your tractor and your job. Choose a product built to last. And make sure your blade has the adjustment features that fit your application.

For business owners, this means better productivity and less downtime.

For equipment dealers, this means loyal customers who trust you to steer them right.

Need a dependable grader blade you can stand behind?

Check out Roadrunner’s 3-Point Tractor Grader Blades

Made in the USA. Built to last. Backed by real people.

Need help choosing the right blade?

Contact Roadrunner and get real answers from folks who actually know their equipment.